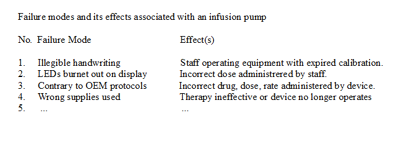

HFEMA infusion pump example

About[]

Health care Failure Mode & Effect Analysis (HFMEA) - A prospective assessment that identifies and improves steps in a process thereby reasonably ensuring a safe and clinically desirable outcome. A systematic approach to identify and prevent product and process problems before they occur. [1]

Basic terms[]

Failure mode: "The manner by which a failure is observed; it generally describes the way the failure occurs."

Failure effect: Immediate consequences of a failure on operation, function or functionality, or status of some item.

Indenture levels: An identifier for item complexity. Complexity increases as levels are closer to one.

Local effect: The Failure effect as it applies to the item under analysis.

Next higher level effect: The Failure effect as it applies at the next higher indenture level.

End effect: The failure effect at the highest indenture level or total system.

Failure cause: Defects in design, process, quality, or part application, which are the underlying cause of the failure or which initiate a process which leads to failure.

Severity: "The consequences of a failure mode. Severity considers the worst potential consequence of a failure, determined by the degree of injury, property damage, or system damage that could ultimately occur."

Uses of FMEA[]

- Development of system requirements that minimize the likelihood of failures.

- Development of methods to design and test systems to ensure that the failures have been eliminated.

- Evaluation of the requirements of the customer to ensure that those do not give rise to potential failures.

- Identification of certain design characteristics that contribute to failures, and minimize or eliminate those effects.

- Tracking and managing potential risks in the design. This helps avoid the same failures in future projects.

- Ensuring that any failure that could occur will not injure the customer or seriously impact a system.

- To produce world class quality products

Advantages[]

These are some examples of its benefits:

- Improve the quality, reliability and safety of a product/process

- Improve company image and competitiveness

- Increase user satisfaction

- Reduce system development timing and cost

- Collect information to reduce future failures, capture engineering knowledge

- Reduce the potential for warranty concerns

- Early identification and elimination of potential failure modes

- Emphasize problem prevention

- Minimize late changes and associated cost

- Catalyst for teamwork and idea exchange between functions

- Reduce the possibility of same kind of failure in future

Types of FMEA[]

- Process: analysis of manufacturing and assembly processes

- Design: analysis of products prior to production

- Concept: analysis of systems or subsystems in the early design concept stages

- Equipment: analysis of machinery and equipment design before purchase

- Service: analysis of service industry processes before they are released to impact the customer

- System: analysis of the global system functions

- Software: analysis of the software functions

References[]

- ↑ VA National Center. Safety Topics. access-date 2013. http://www.patientsafety.gov/SafetyTopics.html